It is hard to tell the differences of kinds of threads. Let's learn about them.

time2019/08/19

- All kinds of threads can be recognized at a glance should be will be of some help to your work.

Threads are everywhere at work. Threads types are variable and it is hard to tell the differences if you do not know their features. All kinds of threads can be recognized at a glance should be will be of some help to your work.

Firstly, let us learn about the basic parameters of threads.

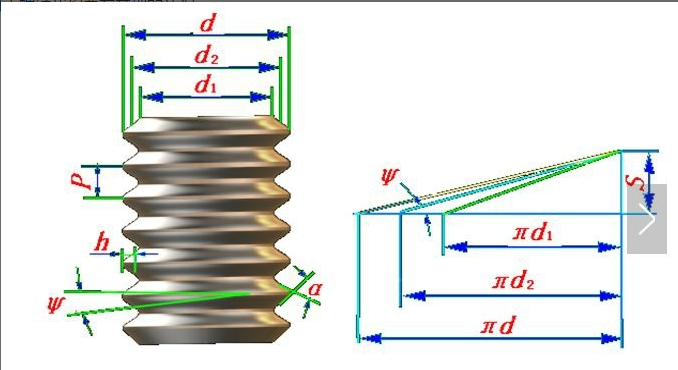

In the above image:

"d" stands for the nominal diameter of thread.

"d1" often used in strength calculations.

"d2" often used in geometric calculations.

"α" is an angle between the two sides of a threaded tooth in an axial section.

"h" is the distance between the top of the tooth and the bottom of the tooth perpendicular to the axis.

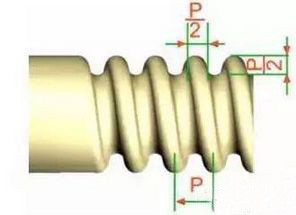

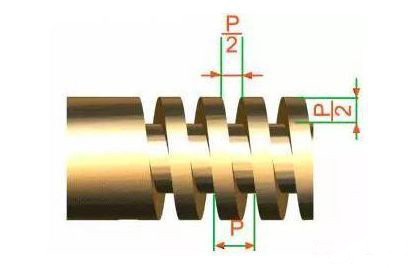

"P" stands for the axial distance between the corresponding points on the adjacent two threaded teeth on the meridian line.

"n" stands for the number of spirals of a thread.

"S" stands for the axial distance to travel along the same helix on the thread, S=nP.

"φ" stands for the Angle between the tangent line of a helix and the plane perpendicular to the axis of the thread.

tan φ=S/πd2=nP/πd2

Then, let's learn more about some common threads.

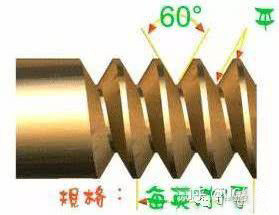

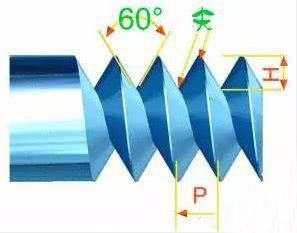

International Metric Thread

The thread Angle is 60 degrees, and the specification is expressed in M

American Standard Thread

The top and root of the thread are flat, with good strength.The thread Angle is also 60 degrees, and the specification is in the number of teeth per inch. The notation is 1/2-10NC.(1/2: outer diameter;10: teeth per inch; for short NC ).

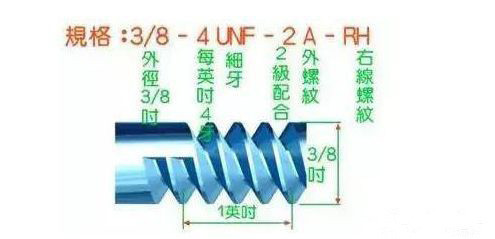

Unified Thread

Made by the United States, the United Kingdom, Canada, for the commonly used British thread.The thread Angle is also 60 degrees, and the specification is in the number of teeth per inch.The thread can be divided into coarse teeth (UNC);Fine thread (UNF);Extra fine teeth (UNEF).The notation is 1/2-10UNC.(1/2: outer diameter;10: teeth per inch;UNC code)

Sharp V Thread

Top and root are pointed, weak strength and infrequently used.The thread Angle is 60 degrees.

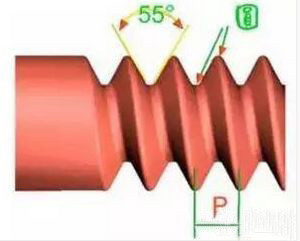

Whitworth Thread

British national standard thread.The thread Angle is 55 degrees, and the symbol is "W".Suitable for rolling process manufacturing.The notation is w1/2 -10.(1/2: outer diameter;10: teeth per inch;W code)

Knuckle Thread

Standard thread specified by DIN in Germany.Suitable for connection of light bulb and rubber tube.The symbol is "Rd"

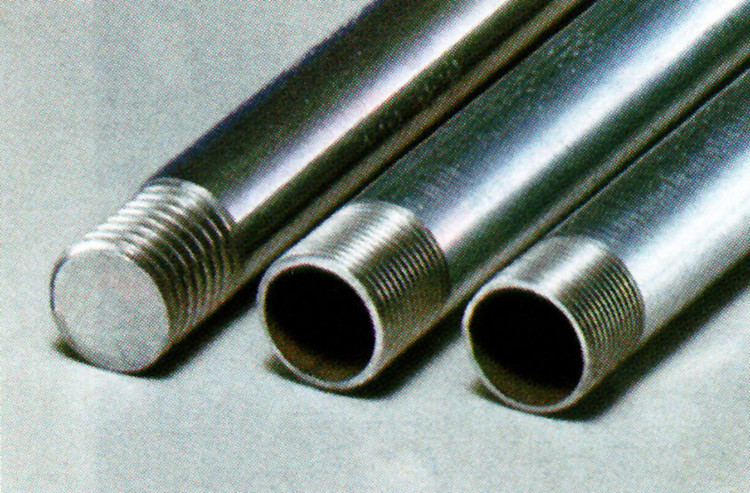

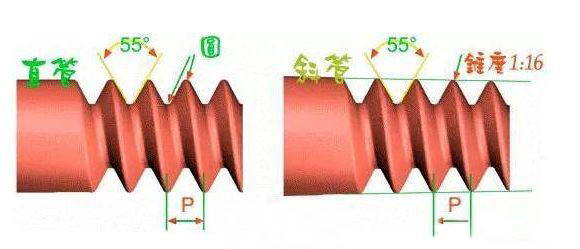

Pipe Thread

Thread used to prevent leakage, often used for gas or liquid fittings.The thread Angle is 55 degrees, which can be divided into straight pipe thread code "P.S., N.P.S." and oblique pipe thread code "N.P.T.", whose taper is 1:16, i.e. 3/4 inch per foot.

Another industry source said, NPT is American standard 60 spinal thread, north American standard, PT is 55 degree conical thread, belonging to wyeth thread, used in Europe and British federation.

Square Thread

Transmission efficiency, second only to the ball thread, and wear after the screw can not be adjusted, for its shortcomings.Generally used for the thread of vice screw and crane.

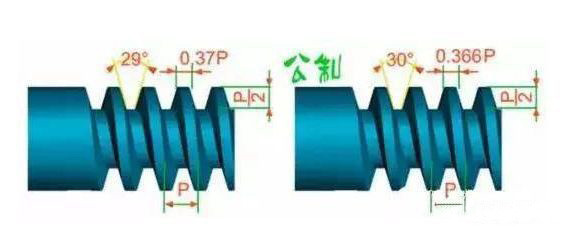

Trapezoidal Thread

Also known as the acme thread.Transmission efficiency is a bit smaller than the square thread, but wear can be adjusted nut.The thread Angle is 30 degrees in metric system and 29 degrees in inch system.Generally used for leading screw of lathe.The symbol is "Tr".

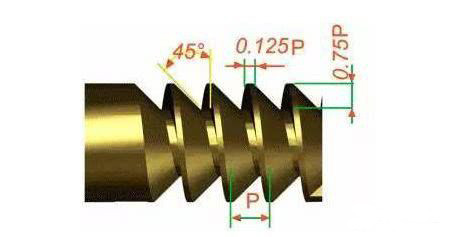

Buttress Thread

Also known as diagonal thread, only suitable for single - direction transmission.Such as screw jack, pressure machine, etc.The symbol is "Bu"

British Standard Thread

The size of a British thread is usually expressed as the number of threads per inch of thread length.For example, a thread of 8 teeth per inch has a pitch of 1/8 inch.

C·Cutting pipe threading machines are mainly for pipe threads. They mention American standard threads, British standard threads, metric threads and even UNC threads available.

Welcome to learn more here. :)