How to choose the right material for your cutting tools ?

time2019/06/05

- Why is the key parts machinery and other equipment so hard and durable, can it process other metals?

The reason why "process other metals" is that the tool materials used are harder than the raw materials, and of course they must have

Why is the key parts machinery and other equipment sohard and durable, can it process other metals?

The reason why "process other metals" isthat the tool materials used are harder than the raw materials, and of coursethey must have:

• High high-temperature hardness (the friction betweenthe machined materials generates a lot of heat, and the hardness of the toolneeds to be maintained at high temperatures)

• Abrasion resistance (does not wear out for longperiods of use)

• Good flexural strength, impact toughness andchemical inertness (to ensure the stability of physical and chemical propertiesunder high temperature and high pressure conditions during processing)

As for "why is it hard and durable", itinvolves the more fundamental atomic/molecular bonding principle in materialsscience. The tool material used is more tightly bonded and the atomic/molecularstructure is less likely to be destroyed. Macroscopically, it is characterizedby “high hardness” and “material capable of cutting low hardness”.

Should they be ferroalloys? How to make them so hardand sharp?

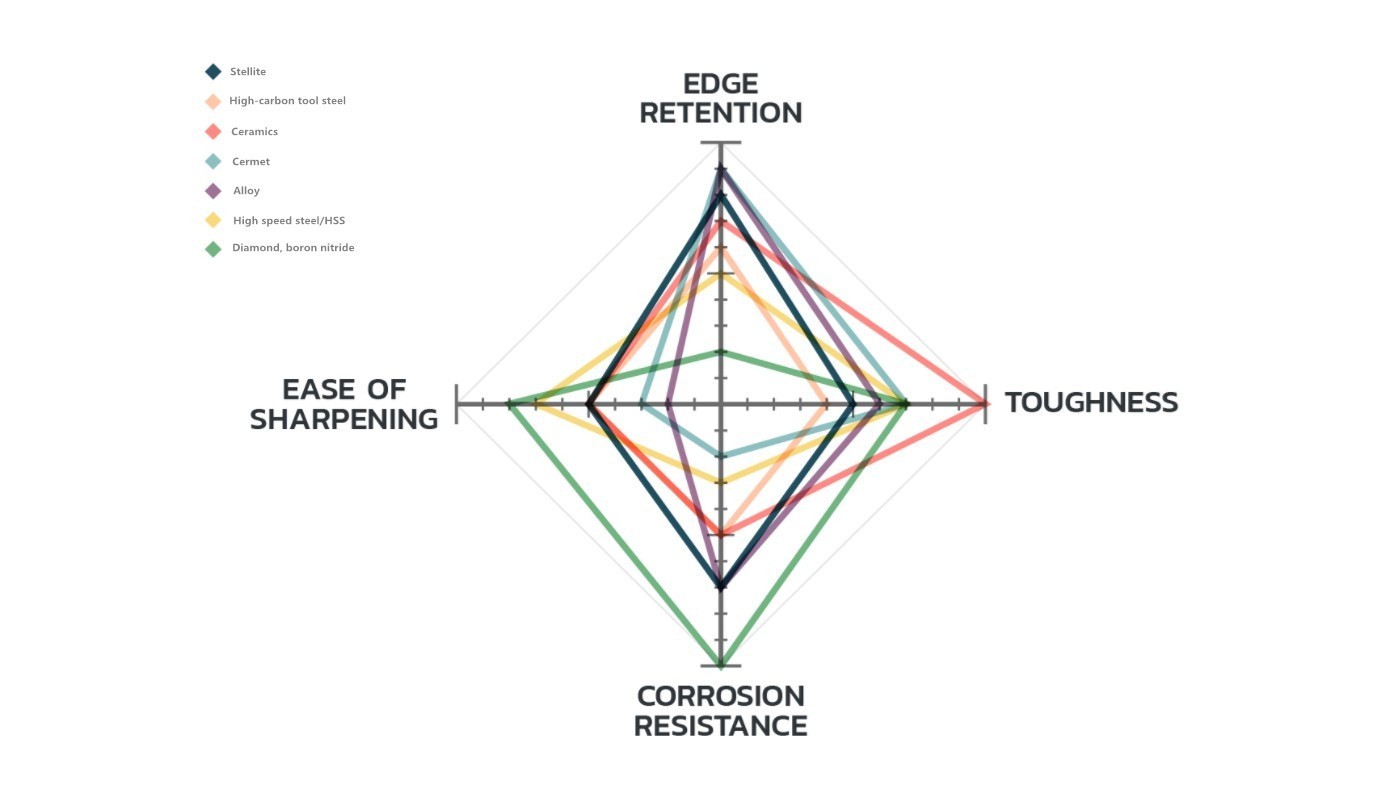

Cutting Wheels can be used but not all iron alloys.Common materials are:

1. 1. High-carbon tool steel: This material is actuallyonly used in the past and has now been phased out. However, it can be used toanswer the latter half of the problem - the hardness of this material afterannealing - quenching - tempering heat treatment can be improved. However, thelower high temperature hardness still limits its use.

2. High speed steel/HSS: It also needs heat treatment, and the hightemperature hardness is greatly improved compared with high carbon tool steel.It is divided into tungsten, molybdenum and cobalt, and is selected accordingto actual processing needs.

3.Stellite: The nature is between HSS and carbide.

4. Alloy: It is made of iron, cobalt and nickel, andis sintered with high hardness powder such as tungsten carbide, vanadiumcarbide and niobium carbide. It is the most widely used material in recentyears. According to the material properties of the cutting workpiece, it isdivided into P type (suitable for general steel), M type (suitable forstainless steel, alloy steel, ductile cast steel and other materials with hightensile strength and difficult to cut), class K (for cast iron and non-ferrous)Metal) three major categories.

5. Cermet: Metal Oxide / Carbide / Nitride / Boride /Silicide + Metal Powder

6. Ceramics

7. Diamond, boron nitride

Further, the tool material may be coated with carbide,nitride or diamond powder only by a method such as chemical vapor deposition(CVD) on the surface, and wear resistance and high-temperature hardness can befurther improved.

In the mechanical field, how do the commonly usedinstruments represent their hardness? Can you describe how hard they are?

In the mechanical field, the hardness is commonly usedin Brinell hardness HB, Vickers hardness HV (hardness test of very thin objectsor parts can be carried out with a small load), Rockwell hardness HR (commonlyused in machinery factories, especially the hardness test of heat-treated parts)several representations. In addition, the Vickers hardness is the same as theBrinell hardness principle, so the two experimental values are close.

In addition to this there is Shore hardness HS. Thecharacteristic is that the relevant experimental equipment is simple and doesnot damage the experimental object, so it is commonly used in the work site,and can be used for the experimental finished product and the processedmaterial, and is basically used for steel parts (objects that must compare thesame Young's modulus).

Four hardness test methods:

• Brinell hardness Using a steel ball/superhard alloyball indenter to measure the surface area/diameter of the pressed material

• Vickers hardness Using a diamond quadrangularpyramid indenter to measure the pit area/diagonal length of the pressedmaterial

• Rockwell hardness Using a steel ball/superhard alloyball indenter/diamond cone indenter to measure the depth of the indentedmaterial pit

• Shore hardness Using a diamond punch to measure therebound height/rebound amount of the punch to the surface of the material

Now our cutting wheels are made of reinforced alloymaterial. It is stronger than normal alloy. The lifetime is 3-5 times more thannormal.